Integrating Artificial Intelligence (AI) and robotics into the manufacturing sector has sparked a revolution in production efficiency. These technologies enhance operational performance, reduce costs, improve safety, and open up new possibilities for innovation. In this article, we’ll examine how AI and robotics are transforming the manufacturing industry, with a particular focus on improving production efficiency. AI and Robotics in Manufacturing: Revolutionizing Production Efficiency.

The Evolution of AI and Robotics in Manufacturing

The goal of efficiency and productivity has long driven manufacturing, but the advent of AI and robotics has brought a seismic shift to the industry. These technologies automate routine tasks, perform complex processes with precision, and enable more intelligent decision-making, improving efficiency.

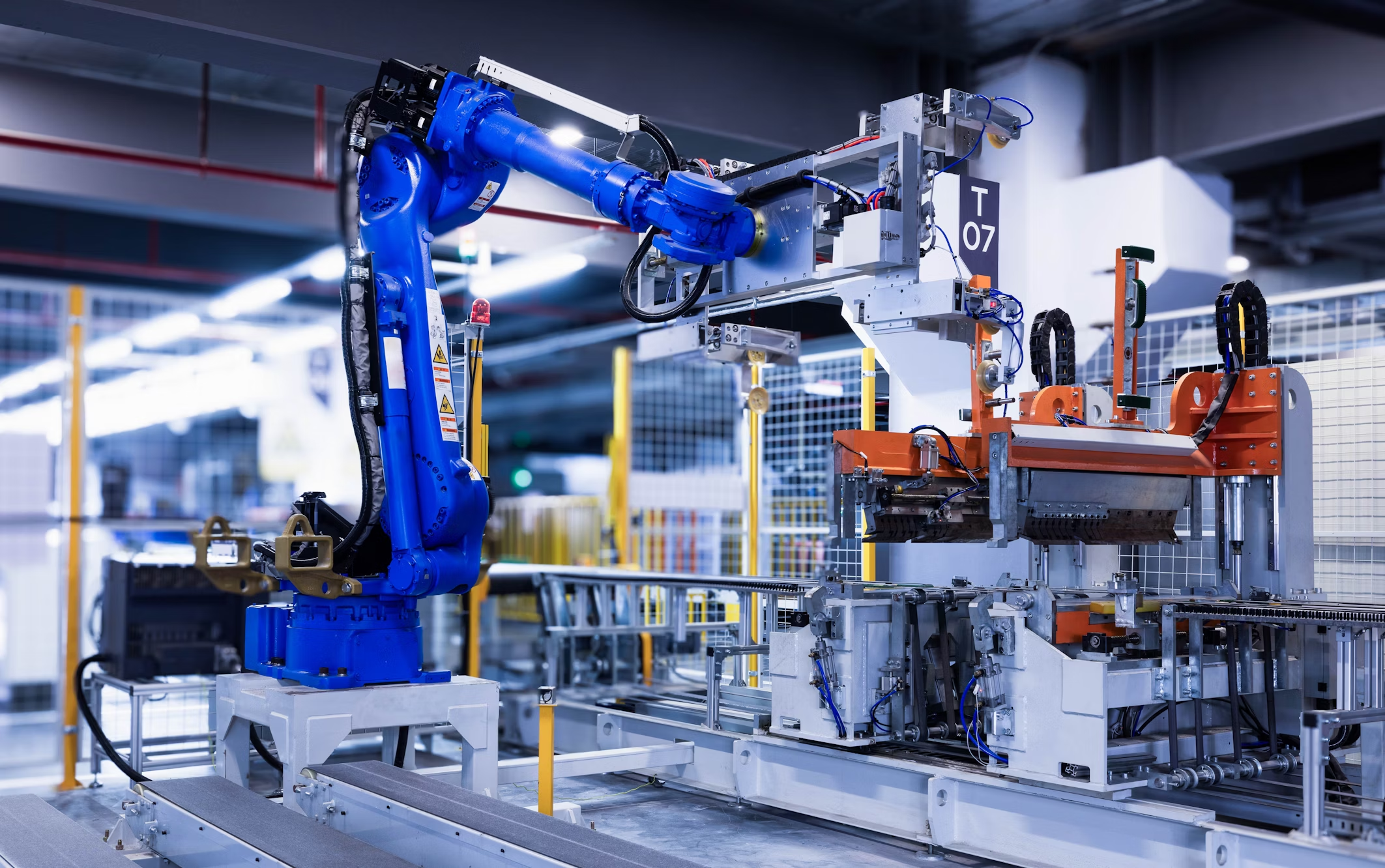

Robotics in manufacturing is not new, but its capabilities have grown exponentially due to advancements in AI. AI-powered robots are capable of self-learning, adapting to new tasks, and performing jobs with a level of consistency and accuracy that surpasses human capabilities. This enables manufacturers to achieve higher production volumes and maintain consistent quality across products.

Enhancing Production Through Automation

Automation is one of the most significant advantages that AI and robotics bring to manufacturing. Robots can perform repetitive tasks such as assembly, welding, packaging, and material handling, which were once labor-intensive and time-consuming. The ability of robots to work continuously without fatigue means production lines can run 24/7, resulting in higher output with fewer delays.

AI, in particular, contributes to optimization within automation systems. Machine learning algorithms continuously analyze production data, fine-tuning robot movements, optimizing scheduling, and improving efficiency. This reduces human error and minimizes costly mistakes, helping manufacturers maintain tight production schedules and meet consumer demands.

Predictive Maintenance for Reduced Downtime

One of the significant costs in manufacturing comes from machine downtime, especially when a critical machine breaks down unexpectedly. AI and robotics can help solve this issue through predictive maintenance, which uses real-time data from sensors embedded in equipment to predict when machines need maintenance. Revolutionizing production efficiency.

By employing machine learning models, manufacturers can monitor equipment conditions, such as temperature, vibration, and pressure, and anticipate potential failures before they occur. This reduces unplanned downtime, extends the lifespan of machinery, and ensures a smoother production process. As a result, companies can avoid costly repairs and production delays.

Improved Product Quality

The ability to maintain consistent product quality is a primary concern for manufacturers. AI and robotics contribute significantly to maintaining and even enhancing product quality. Robots perform tasks precisely, ensuring every product is assembled or manufactured to the specifications. Revolutionizing production efficiency.

AI-driven computer vision systems enable machines to inspect products in real-time, identifying defects or irregularities that might go unnoticed by human workers. This reduces the number of defective products reaching customers and minimizes waste. Early detection of defects also helps correct issues before they become widespread, preventing large-scale production problems.

Greater Flexibility and Customization

Manufacturers today must adapt quickly to changing customer preferences and demands for personalized products. AI and robotics enable more flexibility in production processes, allowing companies to offer customized products without sacrificing efficiency.

For example, automotive manufacturers use AI-powered robots to create customized vehicles. These robots can adjust the assembly process to accommodate various models, colors, and configurations without requiring significant retooling or downtime. This level of flexibility enables manufacturers to efficiently produce a diverse range of products and meet the growing demand for personalized consumer goods.

Addressing Workforce Challenges

While the introduction of robotics and AI systems has raised concerns about job displacement, these technologies also offer opportunities for workforce development. Many routine, physically demanding, or hazardous tasks humans previously carried out are now being automated, freeing workers to focus on higher-value tasks that require creative problem-solving, decision-making, and oversight. Revolutionizing production efficiency.

Moreover, there is a growing need for skilled workers to manage, maintain, and improve AI and robotic systems. As such, manufacturers are investing in training programs to help their employees acquire the skills necessary for a more technologically advanced workplace. This reskilling of the workforce ensures that employees remain valuable contributors to the industry, even as the role of automation increases.

Streamlined Supply Chain and Logistics

AI and robotics also play a significant role in optimizing supply chain operations. Automated guided vehicles (AGVs) and robotic systems can move materials and products across the manufacturing facility, ensuring that materials arrive at the right time and in quantity. This reduces human error, enhances efficiency, and helps maintain a seamless flow of goods throughout the production cycle.

AI-driven systems can predict supply chain disruptions by analyzing historical data and external factors such as weather patterns, political events, and supplier performance. By anticipating potential issues, manufacturers can proactively adjust their supply chain strategies to prevent delays and shortages.

Overcoming Barriers to Implementation

Despite the many benefits, implementing AI and robotics in manufacturing comes with challenges. One of the main hurdles is the initial investment required to purchase and integrate these technologies into existing production lines. However, the long-term savings, higher efficiency, and increased productivity typically outweigh the initial costs. Revolutionizing production efficiency.

Another challenge is ensuring the seamless integration of AI and robotics into the existing workflow. Manufacturers must consider the compatibility of new technologies with their existing infrastructure and processes. This requires a thoughtful approach to system design and extensive employee training to ensure smooth operation.

The Future of AI and Robotics in Manufacturing

The future of AI and robotics in manufacturing is full of promise. Manufacturers can expect even greater automation, productivity, and flexibility as AI algorithms become more sophisticated and robots become more advanced. The introduction of 5G connectivity, for example, will enable robots to communicate and collaborate more effectively in real-time, enhancing their ability to work together and share information.

Collaborative robots, or cobots, are also becoming more prevalent in manufacturing. These robots work alongside humans, performing tasks that complement human workers rather than replacing them. This collaboration between human intelligence and robotic precision is expected to increase productivity and safety in the workplace further. Revolutionizing production efficiency.

AI and robotics undeniably transform the manufacturing industry, providing companies with new tools to increase production efficiency, enhance quality, and reduce costs. By embracing these technologies, manufacturers can position themselves at the forefront of innovation, staying competitive in a rapidly evolving marketplace. As technology continues to grow, the future of manufacturing looks brighter than ever, offering exciting opportunities for growth and advancement.